Maximize Your Engine's Power: A Complete Guide to Engine Internals and Performance Enhancements

Share

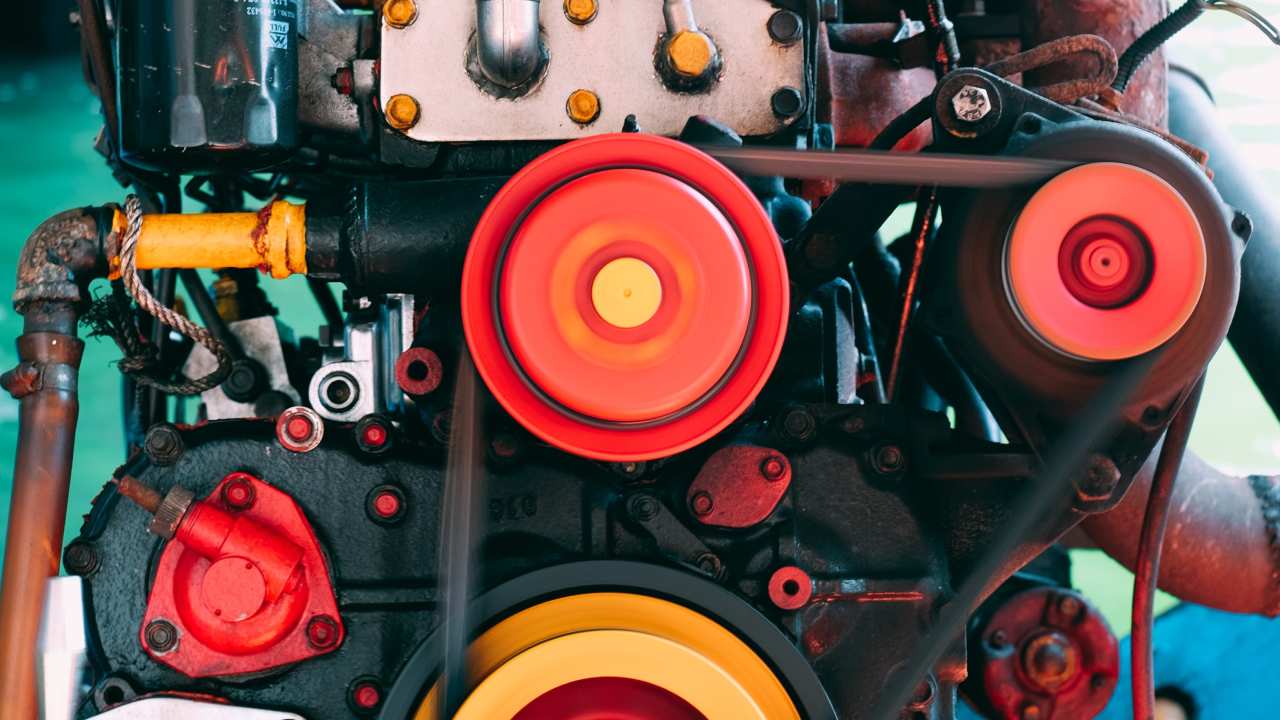

Your car's engine is the heart of its performance, and upgrading its internals can unlock a whole new level of power and efficiency. Engine internals refer to the essential components within the engine that directly contribute to its operation and performance. From pistons and crankshafts to camshafts and cylinder heads, each part plays a crucial role in the combustion process and overall engine efficiency.

In this comprehensive guide, we will delve into the world of engine internals and explore the benefits of upgrading these components. Whether you're a passionate car enthusiast looking to maximize performance on the track or a driver seeking improved everyday driving experience, understanding and enhancing your engine internals can make a significant difference.

By upgrading engine internals, you can achieve increased horsepower, torque, and overall engine responsiveness. These modifications can improve acceleration, throttle response, and even fuel efficiency. However, it's important to note that modifying engine internals requires careful consideration and understanding of the components involved. Proper research, planning, and installation are crucial to ensure optimal results and long-term reliability.

Throughout this guide, we will explore each aspect of engine internals, including pistons, connecting rods, crankshafts, camshafts, cylinder heads, and the engine block. We'll discuss the purpose and function of each component, the available upgrade options, and the considerations to keep in mind when selecting and installing upgraded parts.

Whether you're a seasoned car enthusiast or just starting your journey into engine upgrades, this guide will provide you with valuable insights and practical knowledge to make informed decisions. Remember, optimizing your engine internals is an investment in both performance and reliability, so let's dive in and discover the world of engine internals upgrades.

Understanding Engine Internals

To fully comprehend engine internals and their impact on performance, it's essential to explore the individual components that make up the heart of the engine. Here are the key engine internals you need to understand:

Pistons and Piston Rings

Pistons are cylindrical components that move up and down within the engine cylinders. They play a critical role in the combustion process by compressing the air-fuel mixture and transferring the force generated from combustion to the crankshaft. Piston rings seal the combustion chamber and prevent the mixture from leaking into the crankcase.

Connecting Rods

Connecting rods link the pistons to the crankshaft and convert the reciprocating motion of the pistons into rotational motion. They are subjected to tremendous forces and must be strong and durable. Upgraded connecting rods can handle higher levels of power and torque, reducing the risk of failure under demanding conditions.

Crankshafts

The crankshaft is responsible for converting the linear motion of the pistons and connecting rods into rotational motion. It transfers power from the combustion process to the transmission, which ultimately propels the vehicle. Upgraded crankshafts are designed to handle increased power and offer improved strength and reliability.

Camshafts

Camshafts control the opening and closing of the engine's valves, determining the timing and duration of the valve events. They play a vital role in optimizing engine performance, including power delivery and efficiency. Upgraded camshafts can offer improved lift, duration, and overlap, leading to enhanced horsepower and torque characteristics.

Valvetrain Components

The valvetrain consists of various components, including valves, valve springs, and rocker arms, that work in harmony with the camshafts. Valves regulate the intake and exhaust of the air-fuel mixture, while valve springs ensure proper valve operation. Upgraded valvetrain components can provide increased lift and stability, allowing for higher engine speeds and improved performance.

Cylinder Heads

Cylinder heads sit on top of the engine block and contain the combustion chambers, valves, and ports. They play a crucial role in optimizing airflow and fuel mixture combustion. Upgraded cylinder heads can feature improved port design, larger valves, and optimized combustion chamber shape, resulting in enhanced power and efficiency.

Engine Block

The engine block forms the foundation of the engine and houses the cylinders, crankshaft, and other internal components. It provides structural integrity and stability. Upgraded engine blocks may offer increased strength, improved cooling, and the potential for increased displacement for higher power output.

Understanding these engine internals and their interactions is crucial when considering upgrades for improved performance and reliability. Each component plays a specific role in the engine's operation, and upgrading them can lead to significant gains in power, torque, and overall engine efficiency. In the following sections, we will delve deeper into each component, exploring upgrade options and their impact on performance.

Upgrading Pistons and Piston Rings

When it comes to upgrading engine internals, pistons and piston rings are essential components that can have a significant impact on performance. Let's explore the world of pistons and piston rings and the considerations for upgrading them:

Types of Pistons and their Features

Cast Pistons

Cast pistons are the most common type and are made by pouring molten aluminum into a mold. They are cost-effective and suitable for most applications but may have limitations in terms of strength and thermal efficiency.

Forged Pistons

Forged pistons are created by subjecting aluminum alloy to intense pressure and heat, resulting in a denser and stronger structure. They are highly durable and capable of handling higher levels of power and torque.

Billet Pistons

Billet pistons are machined from a solid block of aluminum, making them incredibly strong and precise. They are typically used in high-performance and racing applications, where extreme strength and weight reduction are critical.

Piston Materials and Coatings

Aluminum Pistons

Aluminum is the most common material for pistons due to its lightweight and excellent thermal conductivity. Upgraded pistons may feature advanced alloys for improved strength and durability.

Coatings

Piston coatings, such as ceramic or thermal barrier coatings, can provide benefits such as reduced friction, improved heat dissipation, and increased wear resistance. These coatings can contribute to enhanced performance and longevity.

Performance Piston Ring Sets

Piston rings are responsible for sealing the combustion chamber, regulating oil consumption, and transferring heat from the piston to the cylinder wall. Upgrading to performance piston ring sets can provide benefits such as reduced friction, improved sealing, and increased durability. Consider factors such as ring material, design, and gap specifications when choosing the right set for your engine.

Installation Tips and Considerations

Proper Measurements

When upgrading pistons and piston rings, accurate measurements of bore diameter, piston-to-wall clearance, and ring end gaps are crucial to ensure proper fitment and performance.

Cylinder Honing

It is essential to properly hone the cylinder walls to the appropriate surface finish to promote proper ring break-in and optimal performance.

Assembly Lubrication

Apply assembly lubricant to the piston skirts, rings, and cylinder walls during installation to reduce friction and prevent damage during initial startup.

Follow Manufacturer Guidelines

Always refer to the manufacturer's instructions and specifications for proper installation procedures, torque values, and any specific recommendations.

Upgrading pistons and piston rings can offer improved power, durability, and overall engine performance. Consider factors such as your engine's power goals, intended usage, and budget when selecting the appropriate components. In the next section, we will explore upgrading connecting rods and their impact on engine performance.

Enhancing Connecting Rods

The connecting rods play a critical role in transferring the reciprocating motion of the pistons to the rotational motion of the crankshaft. Upgrading connecting rods can enhance engine performance, durability, and the ability to handle increased power. Let's delve into the world of connecting rods and the factors to consider when enhancing them:

Upgraded Connecting Rods

Forged Connecting Rods

Forged connecting rods are crafted from high-strength steel or aluminum alloys using a forging process. This manufacturing method results in a dense and robust structure that can withstand higher loads and RPMs. Forged connecting rods are a popular choice for high-performance and racing applications.

Billet Connecting Rods

Billet connecting rods are machined from a solid block of steel or aluminum. They offer exceptional strength and rigidity due to their monolithic construction. Billet connecting rods are often employed in extreme-performance engines where maximum strength and weight reduction are vital.

Forged vs. Billet Connecting Rods

Forged Connecting Rods

With their grain structure aligned along the primary stress points, forged connecting rods are known for their excellent fatigue resistance. They can handle high power levels and endure repeated load cycles without compromising structural integrity.

Billet Connecting Rods

Billet connecting rods offer unparalleled strength and precision due to their one-piece construction. They are particularly well-suited for engines subjected to extreme loads and high RPMs.

Rod Length and Design Considerations

Rod Length

The length of the connecting rod affects the engine's stroke and the dwell time at top dead center (TDC). Longer rods can reduce piston side-loading, improve combustion efficiency, and provide better mechanical advantage.

Design Features

Connecting rod design features, such as H-beam, I-beam, or X-beam configurations, can influence strength, weight, and resistance to bending or twisting forces. These factors should be considered based on the specific requirements of the engine and its intended use.

Connecting Rod Bearing Selection

Connecting rod bearings provide a critical interface between the connecting rod and the crankshaft, ensuring smooth rotational motion. When upgrading connecting rods, it is essential to select bearings that match the specifications and clearance requirements of the new rods. Factors to consider include bearing material, clearance specifications, and compatibility with the crankshaft journal surface.

Enhancing connecting rods can significantly improve engine performance, especially in high-stress applications. By upgrading to stronger and lighter rods, you can enhance the engine's ability to handle increased power and RPMs. In the next section, we will explore crankshafts and their role in engine performance and durability.

Optimizing Crankshafts

The crankshaft is the backbone of the engine, converting the reciprocating motion of the pistons into rotational motion. Upgrading and optimizing the crankshaft can have a significant impact on engine performance, durability, and smooth operation. Let's delve into the world of crankshafts and explore various ways to optimize them for enhanced engine performance:

Performance Crankshaft Options

Forged Crankshafts

Forged crankshafts are crafted from high-strength steel and undergo a forging process that aligns the grain structure for superior strength. They can handle increased power and torque output and are commonly used in high-performance and racing applications.

Billet Crankshafts

Billet crankshafts are machined from a solid block of high-quality steel. They offer exceptional strength, precision, and customization options. Billet crankshafts are often employed in extreme-performance engines where maximum strength and reliability are paramount.

Forged vs. Billet Crankshafts

Forged Crankshafts

Forged crankshafts are known for their exceptional strength and resistance to fatigue. They are capable of withstanding higher loads and RPMs, making them suitable for high-performance applications. The forging process enhances the grain structure, resulting in improved durability and reliability.

Billet Crankshafts

Billet crankshafts are machined from a solid piece of steel, providing excellent strength and precision. Their monolithic construction allows for more intricate designs and customization options. Billet crankshafts are often chosen for extreme-performance engines, where strength and lightweight characteristics are critical.

Stroke and Offset Considerations

Stroke

The stroke length refers to the distance the piston travels from top dead center (TDC) to bottom dead center (BDC). Altering the stroke length can change an engine's displacement and affect power characteristics. Longer strokes typically increase torque output, while shorter strokes favor higher RPM potential.

Offset

Crankshaft offset refers to the distance between the crankshaft's main journal centerline and the centerline of the connecting rod journal. Offset cranks can influence piston dwell time at TDC and improve combustion efficiency. However, offsetting the crankshaft also affects rod angle and side-loading, requiring careful consideration during the engine build.

Balancing and Blueprinting the Crankshaft

Balancing

Balancing the crankshaft is crucial for smooth engine operation and reduced vibration. Balancing the crankshaft involves equalizing the weight distribution to minimize vibrations and ensure smooth rotation. This process typically includes counterweights and precise machining to achieve optimal balance.

Blueprinting

Blueprinting the crankshaft involves meticulous measurements and machining to ensure precise tolerances and clearances. This process enhances overall engine performance, reduces friction, and maximizes power output. Blueprinting involves checking journal sizes, runout, and aligning the main and rod bearing bores for optimal performance.

Properly optimizing the crankshaft is essential for maximizing engine performance, reducing stress on engine components, and increasing reliability. It's crucial to consult with knowledgeable engine builders or professionals when selecting and optimizing crankshafts to ensure compatibility with other engine components and achieve the desired performance goals.

Camshaft Upgrades for Increased Performance

Camshafts are a critical component of an engine's valvetrain system, responsible for controlling the opening and closing of the intake and exhaust valves. Upgrading the camshaft can have a significant impact on engine performance, altering power delivery, torque characteristics, and overall efficiency. In this section, we will delve deeper into camshaft upgrades, exploring the different types of camshafts, duration, lift, timing considerations, camshaft materials and coatings, and valve train upgrades necessary for optimal performance.

Types of Camshafts

Hydraulic Camshafts

Hydraulic camshafts are the most common type found in street and performance engines. They utilize hydraulic lifters that automatically adjust for valve clearance, eliminating the need for periodic adjustment. Hydraulic camshafts are known for their smooth operation, quietness, and ease of maintenance. They are suitable for a wide range of applications, offering good low-end torque and drivability.

Solid Camshafts

Solid camshafts are favored in high-performance and racing engines due to their ability to provide precise valve control and high RPM potential. Unlike hydraulic camshafts, solid camshafts require manual valve lash adjustment to maintain optimal performance. Solid camshafts are known for their aggressive profiles, increased lift, and extended RPM range. They offer improved throttle response and top-end power but may sacrifice some low-end torque and idle quality.

Roller Camshafts

Roller camshafts combine the benefits of both hydraulic and solid camshafts. They feature small wheels or "rollers" on the cam lobes that come into contact with the lifters, reducing friction and wear. Roller camshafts provide improved valve lift, reduced frictional losses, and increased durability compared to other camshaft types. They are commonly used in performance engines where longevity and high RPM operation are desired.

Duration, Lift, and Timing Considerations

Duration

Camshaft duration refers to the length of time the valves remain open during each combustion cycle. Duration is measured in degrees of crankshaft rotation and can be divided into two components: intake duration and exhaust duration. Longer duration camshafts keep the valves open for a greater period, allowing more air and fuel mixture to enter the combustion chamber or exhaust gases to exit. Longer duration typically results in increased power at higher RPM but may sacrifice low-end torque.

Lift

Camshaft lift refers to the distance the valve opens off its seat during operation. Higher lift camshafts allow more air and fuel mixture to enter the combustion chamber or exhaust gases to exit, improving overall engine performance. Lift is typically measured in inches or millimeters and should be selected based on the engine's specific requirements and intended use.

Timing

Camshaft timing refers to the relationship between the crankshaft and camshaft, determining when the valves open and close in relation to the piston position. Proper timing is crucial for achieving optimal engine performance and efficiency. Advancing or retarding the camshaft timing can alter power delivery characteristics, torque curve, and overall performance. Precise timing adjustments are typically made during the installation and tuning process.

Camshaft Materials and Coatings

Camshaft Materials

Camshafts are commonly made from cast iron, steel alloys, or billet materials. Each material has its own characteristics, such as strength, durability, and weight. Steel alloys and billet camshafts are popular choices for high-performance applications due to their increased strength and ability to withstand high stress and RPM levels.

Camshaft Coatings

Camshaft coatings are applied to enhance durability, reduce friction, and improve performance. Some common coatings include nitride, which provides excellent wear resistance, and DLC (Diamond-Like Carbon), known for its low friction properties. Coatings can improve the overall lifespan of the camshaft and reduce the need for frequent replacements.

Valve Train Upgrades for Camshaft Compatibility

When upgrading the camshaft, it is essential to consider the entire valvetrain system to ensure compatibility and optimize performance. The following components may require upgrades or adjustments:

Valve Springs: Upgrading valve springs is often necessary to match the increased lift and duration of a high-performance camshaft. Stiffer valve springs are required to prevent valve float at high RPM and ensure proper valve control.

Retainers and Keepers: Upgraded retainers and keepers may be necessary to accommodate the increased lift and stress caused by a high-performance camshaft.

Lifters: Hydraulic lifters are commonly used with hydraulic camshafts, while solid lifters are used with solid camshafts. Roller lifters are often used with roller camshafts. Choosing the appropriate lifters that match the camshaft type is crucial for proper operation and longevity.

Pushrods: High-performance camshafts may require stronger and more rigid pushrods to handle the increased loads and prevent deflection.

Rocker Arms: Upgrading to performance rocker arms can improve valvetrain stability and durability, especially when using high-lift camshafts.

By understanding the different types of camshafts, considering duration, lift, timing factors, selecting suitable materials and coatings, and addressing valve train upgrades, you can effectively enhance the performance of your engine through camshaft upgrades. Remember to consult with experienced engine builders or professionals to ensure proper selection, installation, and tuning for optimal results.

Cylinder Head Modifications

Cylinder heads play a crucial role in the overall performance of an engine, dictating the airflow, combustion efficiency, and power output. By upgrading and modifying the cylinder heads, you can unleash the true potential of your engine. In this section, we will delve into various cylinder head modifications, including porting and polishing, valve modifications, combustion chamber modifications, and upgrading valve springs, retainers, and lifters.

Porting and Polishing

Porting and polishing involve reshaping and smoothing the intake and exhaust ports of the cylinder head to optimize airflow. By carefully removing imperfections, rough surfaces, and restrictions, porting and polishing can increase the flow of air and fuel mixture into the combustion chamber and improve exhaust gas evacuation. This modification enhances cylinder filling, combustion efficiency, and overall engine performance.

Intake Porting

Intake porting focuses on increasing the volume and velocity of the incoming air and fuel mixture. This can be achieved by enlarging and reshaping the intake ports, removing any obstructions, and optimizing the port shape for better airflow dynamics.

Exhaust Porting

Exhaust porting aims to improve the evacuation of exhaust gases from the combustion chamber. By enlarging and reshaping the exhaust ports, the exhaust gas flow can be optimized, reducing backpressure and enhancing engine breathing.

Polishing

After porting, the ports and the combustion chamber surfaces can be carefully polished to further smooth out any rough areas. Polishing helps minimize turbulence, improve airflow, and reduce the likelihood of carbon buildup.

Valve Modifications

Valve Size: Upgrading to larger valves can increase airflow and improve cylinder filling, especially in high-performance applications. However, larger valves may require modifications to the valve seats, valve guides, and other components to ensure proper fit and operation.

Valve Shape: Modifying the shape of the valves, such as a radius or tulip profile, can improve flow characteristics and enhance combustion efficiency. Valve profiling should be done in conjunction with porting and polishing to ensure optimal airflow throughout the entire intake and exhaust system.

Valve Material: Upgrading to performance valves made from materials like stainless steel or titanium can offer increased strength, durability, and heat resistance. These materials can withstand higher operating temperatures and reduce the likelihood of valve deformation or failure.

Combustion Chamber Modifications

Modifying the combustion chamber can optimize fuel atomization, flame propagation, and combustion efficiency. The following modifications can be performed:

Combustion Chamber Shape: Altering the shape of the combustion chamber can promote better airflow, fuel distribution, and flame propagation. Bowl shaping, squish area modifications, and valve seat reshaping are common techniques to improve combustion efficiency.

Compression Ratio Modifications: Changing the combustion chamber volume or piston design can alter the compression ratio. Adjusting the compression ratio can optimize performance for specific applications, such as improving low-end torque or increasing high-end power.

Upgraded Valve Springs, Retainers, and Lifters

When making significant modifications to the camshaft or valve train, upgrading valve springs, retainers, and lifters is often necessary. High-performance camshafts may require stiffer valve springs to prevent valve float at high RPM, ensure proper valve control, and avoid potential valve-train damage. Upgraded retainers and lifters can also provide increased durability, reduced deflection, and improved valvetrain stability.

Properly modifying and upgrading cylinder heads is a complex process that requires precision, knowledge, and experience. It is crucial to consult with experienced engine builders or professionals who can analyze your specific engine setup, goals, and performance requirements to provide tailored recommendations and perform the necessary modifications for optimal results.

Engine Block Enhancements

The engine block serves as the foundation of the entire engine, housing various crucial components and providing structural integrity. Enhancing the engine block can significantly impact engine performance, durability, and power potential. In this section, we will explore different engine block enhancements, including reinforcement techniques, cylinder boring and honing, main studs and girdles, and the use of cylinder sleeves and Darton sleeves.

Engine Block Reinforcement

Block Deck Reinforcement: Reinforcing the block deck involves strengthening the top surface of the engine block where the cylinder head attaches. This can be achieved through techniques such as block decking, which involves machining the block deck to ensure it is perfectly flat and provides a stable surface for the cylinder head gasket.

Main Cap Support: Installing main cap supports or girdles can help increase the rigidity and strength of the engine block. These aftermarket components help distribute the load and reduce block flexing, especially in high-performance applications with increased power levels and stress on the bottom end.

Cylinder Boring and Honing

Cylinder Boring: Cylinder boring is a process of enlarging the cylinder bores to accommodate larger pistons or to remove any imperfections or wear. This process involves carefully machining the cylinder walls to achieve the desired diameter and surface finish for optimal piston-to-wall clearance and proper sealing.

Cylinder Honing: Honing involves creating a crosshatch pattern on the cylinder walls using specialized honing tools. This pattern improves oil retention, promotes piston ring seating, and facilitates proper lubrication. Honing also removes any remaining machining marks or glaze, ensuring a smooth and uniform surface.

Main Studs and Girdles

Main Studs: Upgrading to high-strength main studs provides improved clamping force between the main caps and the engine block. This helps prevent main cap movement, maintains consistent bearing clearances, and enhances overall bottom-end stability. Main studs are particularly beneficial in high-performance applications with increased cylinder pressures and RPM.

Girdles: Main girdles or main caps girdles are additional structural components that reinforce the main bearing area of the engine block. These girdles provide additional support and rigidity, reducing block flex and minimizing the risk of main bearing cap movement. Girdles are commonly used in high-performance and racing applications to ensure maximum durability and reliability.

Cylinder Sleeves and Darton Sleeves

Cylinder Sleeves

Cylinder sleeves are cylindrical liners inserted into the cylinder bores to provide a new surface for the piston to move in. They can be used to repair damaged or worn cylinders or to increase the bore size for performance purposes. Sleeving can strengthen the block and allow for larger piston sizes and increased displacement.

Darton Sleeves

Darton sleeves are a specific type of cylinder sleeves known for their strength and durability. They are commonly used in high-performance and forced induction applications where extreme cylinder pressures and temperatures are present. Darton sleeves provide excellent support for the cylinder walls, reduce cylinder distortion, and improve overall engine reliability.

Enhancing the engine block requires careful planning, precision machining, and the use of high-quality components. It is essential to consult with knowledgeable engine builders or professionals who can guide you in selecting the appropriate enhancements for your specific engine setup, power goals, and performance requirements.

Balancing and Blueprinting the Engine

Achieving optimal balance and precision in an engine is crucial for maximizing performance, reducing vibrations, and improving overall reliability. Balancing and blueprinting the engine involves meticulous measurement, adjustment, and fine-tuning of various internal components to ensure harmonious operation. In this section, we will explore the importance of engine balancing, the process of blueprinting an engine, as well as the role of harmonic balancers, crankshaft dampers, flywheel, and flexplate balancing.

Importance of Engine Balancing

Balance and Vibration

Engine balancing is the process of equalizing the weight and distribution of rotating and reciprocating components to minimize vibrations and ensure smooth operation. Balanced engines experience reduced vibrations, which improves driver comfort, reduces stress on engine components, and enhances overall performance.

Internal Component Wear

An unbalanced engine can lead to excessive wear on internal components, such as crankshafts, bearings, pistons, and connecting rods. Proper balancing helps distribute loads evenly, reducing the strain on these components and extending their lifespan.

Blueprinting the Engine for Maximum Efficiency

Measuring and Machining

Blueprinting an engine involves carefully measuring and machining critical components to precise tolerances and specifications. This process ensures consistency and uniformity throughout the engine, resulting in optimal performance and efficiency.

Clearance and Fitment

Blueprinting includes checking and adjusting critical clearances, such as piston-to-wall clearance, bearing clearances, valve-to-piston clearance, and valve lash. These adjustments help achieve optimal fitment and operation, minimizing friction and maximizing power output.

Harmonic Balancers and Crankshaft Dampers

Harmonic Balancers

Harmonic balancers, also known as vibration dampers or crankshaft pulleys, help reduce torsional vibrations and maintain the stability of the crankshaft. They consist of a metal hub and a rubber or elastomer ring that absorbs and dissipates vibrations generated by the engine's reciprocating and rotating components.

Crankshaft Dampers

Crankshaft dampers are additional components used to further reduce torsional vibrations in the crankshaft. They are typically integrated into the front section of the crankshaft and work in conjunction with the harmonic balancer to minimize vibration-induced stress on the crankshaft and other engine parts.

Flywheel and Flexplate Balancing

Flywheel Balancing

The flywheel, in manual transmission-equipped engines, or flexplate, in automatic transmission-equipped engines, plays a crucial role in the engine's rotating assembly. Balancing the flywheel or flexplate ensures smooth engine operation, prevents vibrations, and maintains proper clutch engagement or torque converter operation.

Professional Balancing Services

Achieving precise balance in the flywheel or flexplate often requires professional balancing services. These services involve accurately measuring and removing material from specific areas of the component to achieve the desired balance.

Balancing and blueprinting an engine is a meticulous process that requires expertise and specialized equipment. It is recommended to seek the assistance of experienced engine builders or professionals who can accurately measure, adjust, and balance the internal components to achieve optimal performance and reliability.

Engine Internals Upgrades for Forced Induction

Forced induction, whether through turbocharging or supercharging, introduces additional stresses and demands on engine internals. To ensure the engine can handle the increased power and boost pressure, specific upgrades to key components are necessary. In this section, we will delve into the considerations for turbocharged and supercharged applications, as well as explore the upgrades required for pistons, connecting rods, camshafts, and cylinder heads in boosted engines.

Considerations for Turbocharged and Supercharged Applications

Increased Cylinder Pressure

Forced induction systems generate higher cylinder pressures, leading to increased stress on the engine internals. It is crucial to choose components capable of withstanding the added pressure and heat generated by forced induction.

Heat Management

Turbochargers and superchargers generate significant heat, which can affect engine performance and reliability. Upgrades that improve heat dissipation and management, such as enhanced cooling systems and thermal barrier coatings, are essential for maintaining optimal operating conditions.

Piston and Connecting Rod Upgrades

Forged Pistons

Forged pistons offer superior strength and durability compared to stock cast pistons. They are capable of withstanding higher combustion pressures and temperatures, making them ideal for forced induction applications.

Upgraded Piston Rings

Upgraded piston rings with enhanced sealing capabilities are crucial for maintaining proper compression and preventing boost pressure from leaking into the crankcase.

High-Strength Connecting Rods

Upgraded connecting rods made from stronger materials, such as forged steel or titanium, are necessary to handle the increased forces exerted on the rods due to forced induction.

Camshaft Selection for Forced Induction

Duration and Lift Considerations

Camshafts designed for forced induction applications often feature different duration and lift profiles to optimize power delivery within the boosted range. These camshafts help maximize airflow and ensure proper valve timing for efficient combustion.

Valve Overlap

Camshafts with reduced valve overlap can prevent boost pressure from escaping through the exhaust during the intake stroke, improving overall efficiency and power output.

Cylinder Head Modifications for Boosted Engines

Increased Flow Capacity

Cylinder head modifications, such as porting and polishing, can improve airflow into and out of the combustion chamber, allowing for better intake and exhaust gas flow. This enhancement helps maximize power potential in forced induction engines.

Reinforced Valvetrain Components

Upgrading to stronger valve springs, retainers, and lifters is essential to prevent valve float and maintain proper valve control under high boost conditions.

It is important to consult with experienced engine builders or performance shops specializing in forced induction applications to ensure the selection and installation of the appropriate upgrades. Properly matched components and modifications tailored to forced induction engines will enhance both power output and engine reliability.

Engine Tuning and Management

Achieving the full potential of upgraded engine internals requires precise tuning and management to optimize performance and ensure reliability. Engine tuning involves adjusting various parameters and settings to maximize power output, fuel efficiency, and drivability. In this section, we will discuss the key aspects of engine tuning and management, including fueling, ignition timing, air/fuel ratio, and the role of engine management systems.

Fueling and Ignition Timing

Fuel Injector Upgrades

Upgraded fuel injectors with higher flow rates are often necessary to provide adequate fuel delivery for increased power levels. Proper sizing and calibration of injectors ensure optimal fueling under various operating conditions.

Ignition Timing Optimization

Adjusting the ignition timing to suit the specific characteristics of the engine and fuel being used is crucial for maximizing power and preventing detonation. Advanced ignition timing control systems can provide precise timing adjustments for different load and rpm ranges.

Air/Fuel Ratio

Wideband Oxygen Sensors

Installing wideband oxygen sensors allows for accurate monitoring and adjustment of the air/fuel ratio. Maintaining the proper stoichiometric ratio ensures efficient combustion and avoids running too rich or too lean, which can adversely affect performance and engine longevity.

Electronic Fuel Management

Upgraded engine management systems with advanced fuel control capabilities, such as programmable ECUs (Engine Control Units), enable precise tuning of the air/fuel mixture for optimum performance. These systems offer greater flexibility and customization compared to stock ECUs.

Engine Management Systems

Standalone Engine Management Systems

Standalone engine management systems offer comprehensive control over engine parameters, allowing for precise tuning and customization. These systems provide advanced features, including data logging, boost control, launch control, and traction control, to optimize engine performance.

Piggyback Engine Management System

Piggyback systems work in conjunction with the stock ECU, intercepting and modifying signals to achieve desired engine performance. They offer flexibility for tuning without completely replacing the factory ECU.

Dyno Tuning

Dyno tuning involves running the engine on a dynamometer, which allows for real-time measurement and adjustment of engine parameters. This tuning method provides accurate and controlled testing conditions, resulting in optimized performance.

Working with an experienced tuner who understands the intricacies of engine internals and forced induction systems is crucial for achieving the best results. Custom tuning involves tailoring the engine calibration to the specific modifications and performance goals of the vehicle.

Pedal Commander®

Pedal Commander® is a device designed to optimize throttle response and improve performance. While it is not an engine tuning solution, it will let you tune your throttle response. The Pedal Commander® offers precise control over throttle sensitivity, allowing drivers to tailor the throttle response to their preferences and driving style. With its 2-year warranty and a 30-day money-back guarantee, the Pedal Commander® is a reliable and versatile option for those looking to enhance their driving experience.

Incorporating engine internals upgrades and utilizing performance-enhancing devices like the Pedal Commander® can transform your vehicle into a high-performance machine, delivering exhilarating driving experiences and unmatched power on the road or track.

Remember to prioritize proper installation, regular maintenance, and professional tuning to ensure the longevity and reliability of your upgraded engine. By following best practices and working with knowledgeable professionals, you can enjoy the benefits of enhanced performance while maintaining the integrity of your engine.

Whether you are a beginner starting your journey into performance modifications or an experienced enthusiast seeking to push the limits of your vehicle, upgrading engine internals opens up a world of possibilities. Embrace the power, unleash the potential, and experience the thrill of a high-performance engine.